Steelbro’s New Next Generation SB363 Sidelifter

Steelbro have a limited number of units available for immediate delivery. Check out the list below or get in touch for details. Enquire Now

SB362 Steelbro Gooseneck Sidelifter – Cost effective transportation, loading and unloading of containers. Gooseneck trailer supports carrying of 20’ and 40’ HC containers in height restricted areas.

Stock Unit Product Features

For further details and pricing enquire now

Stock Unit SB9881 Product Features

For further details and pricing enquire now

Operators wishing to transport and deliver lighter loads more economically may find this new model becomes their first choice. Simply put, the design seamlessly combines the very best of both worlds – low tare weight and proven strength and durability in one unit. Faced with two competing yet important design objectives, Steelbro set out to produce a sidelifter that met the optimum needs of low tare weight, while at the same time delivering proven strength and durability.

The SB362 has been tried and tested in New Zealand and Australia where it enjoys a strong presence in the commercial road transport market. For some years the SB362 has become a top selling product in those countries. Many operators approve of the technology and have been impressed by its performance, e.g. having the ability to lift up to a 36-tonne weight yet answering the payload challenge.

With a 36-tonne lifting capacity, the sidelifter is quick and stable and boasts an outreach of more than four metres to provide ease of operation. The SB362 is available with a separate power pack system with Kubota engine. This means that the sidelifter can operate with any truck without any specific hydraulic fittings, and gives more flexibility for operators with a fleet of trucks. In addition, this model will handle 20 ft containers, 40 ft containers as well as 2 x 20 ft containers side by side. It will also handle the double stacking of containers, an added feature when space is at a premium.

Although based on an existing successful design, the SB362 you’ll see in Malaysia has been carefully modified for the Malaysian market. Steelbro designers gave this customised unit a heavy-duty chassis to cater to the Malaysian environment and conditions. The design uses similar running gear to the already popular Steelbro model (SB450) for seamless integration with other units in the fleet. Sidelifters are also JPJ and Dosh compliant.

The New Malaysia model is not expected to replace the SB450 unit, but will offer an alternative choice, and in some cases supplement the existing fleet. According to Steelbro, operators are still expected to choose the SB450 when conditions are extreme and call for a more rugged sidelifter unit with a stronger lifting capacity. With the SB450, transfers of containers weighing up to 45 tonnes can be made easily within a safe working envelope.

Operators who include both models in their fleet will benefit from similar running gear on the chassis for ease of maintenance and spare parts. In addition, both the SB362 and the SB450 utilise the same controller, cable and remote which means that no additional operator training is required.

The Malaysian team is excited to launch this product into the country. Steelbro SE Asia Regional Manager, Andy Ersalle says, “Steelbro Malaysia strives to exceed the expectations of our customers as we now offer a range of options in the sidelifter product line i.e. units for both heavy duty use and regular use to meet customer demand. The new Steelbro SB362 sidelifter for regular use is being introduced at a competitive market price offering great value without compromising with quality. This long-awaited model to the market, for small and medium size industries is expected to deliver cost reduction savings for our customers as well as being capable of delivering a safe working load of up to 36 tonnes. It’s one of the best valued sidelifters in the industry designed with safety and stability in mind as well as offering a long service life.”

Steelbro will be at the Malaysia Commercial Vehicle Expo (MCVE) in Kuala Lumpur from 20-22 June 2019 and the team looks forward to demonstrating the features of this new sidelifter.

First published in Asian Trucker Issue May/June 2019

Designers at Steelbro are constantly improving their rugged SB450 sidelifter without compromising on ‘safety’ which continues to be their number one focus. Throughout the design process, a constant eye is kept on safety. Although the SB450 sidelifter was built to work under the most extreme of conditions, transfers of containers weighing up to 45 tonnes can still be made easily within a “safe” working envelope.

An emergency stop button is located on the remote control that will shut down the engine and stop all operations once the button is activated.

The sidelifter stabiliser legs are fitted with an interlock system that prevent lifts from being attempted without the stabiliser legs being deployed. A plunger switch is fitted to the stabiliser housing and is activated when the foot has positive downward pressure. Until that time, the lifting arms are disabled.

The hydraulic system is fitted with pilot operated over-centre valves on the crane arm cylinders. These are factory pre-set to cope with unforeseen shock loads or attempts to lift more than the crane’s maximum lifting capacity.

Special over-centre valves:

The hydraulic system is also fitted with a High Speed/Load Sense Unloader Valve which limits working pressure when operating in high speed mode. This prevents the engine from overload.

The team at Steelbro has also developed a way of operating a sidelifter with safe and speedy precision. They found a way of achieving smoother, more stable container loading and unloading that gives more speed control, allows for higher speeds, and reduced stress fatigue on the crane arms. This is known as “Proportional Control”.

Using “Proportional Control”, loading a container onto a sidelifter is possible in less than five minutes. The Danfoss proportional controls built into each system provide for smooth control of the container load at all times, ensuring maximum safety and product reliability. The Steelbro sidelifter can be used to place a shipping container with precision anywhere a truck can access. Containers are handled with fine movements and with varying amounts of speed and can be positioned accurately, quickly, easily and – importantly – safely, irrespective of weight.

Support for the Proportional Control system is overwhelming. In Malaysia, operators at SMG Mega Sappire described the sidelifter “…as having more customer control than other units. They are more reliable and safer to load and unload heavy containers. They were found to be safer to operate with the joystick.”

Safety is key for a growing number of Malaysian operators. Mr Tee Wah Meng, Director of Viva Haulage Sdn Bhd says “The sidelifter has increased the speed of our operation and the volume of containers we can handle. Our operators at Viva have described the Steelbro units as convenient to use and safe to operate.”

Sidelifter operators at Nova Haulage are huge fans too. One operator described the Steelbro unit as “…very safe to work with. It has improved the way I do my work.” Another operator said “it’s the most reliable sidelifter to work with in any conditions.” According to Nova’s Mr Siva, “We have used competitor units – they are commercially more expensive and generally result in more downtime in operation due to their lightweight design and manufacture. We chose the Steelbro units based price, durability and safety and we like the double stacking feature. We consider Steelbro to be the pioneer in Malaysia.”

Manager of Klang based Troplast, Ms Lee says “The fleet of Steelbro sidelifters is crucial to the efficiency of our operation. The units have definitely helped our operation by increasing the number of containers we can move and safety is improved significantly… the company faces new growth challenges and will continue to strive to achieve quality services, whilst keeping safety as a top priority.”

When choosing Steelbro as the supplier, Ng Yau Hon, Operations Manager at Yal Bulk Packing Services SDN BHD, says “Choosing the right equipment is essential for our business. We looked at price, safety, durability and return on investment.”

First published in Asian Trucker Issue 46

A former lecturer, Steelbro’s Regional Manager for South East Asia, Andy Ersalle shares his experience and aspirations in the equipment industry.

“You cannot just study business in a classroom. You have to go out and do things, get things done, make profit, and experience it. That is what a real businessman does.”

Although he was himself a student of Business Administration at the University of Lincoln in United Kingdom where he obtained a master’s degree in 2002, Steelbro Container Handling Solutions (Steelbro) Regional Manager for South East Asia, Andy Ersalle had always believed that hands-on experiences are the best teachers. During his master’s degree programme, he went through a management training programme at an Ivy League group company where he was the personal assistant to the managing director.

“I gained a lot of experience and knowledge in the business industry from working with him. We did a lot of business projects and negotiations with local and international projects, as well as government ventures. I also learned to manage up to 400 manpower, which is something you cannot learn in university. I was lucky to learn all of this from someone whom I consider a mentor, for five years,” he told Asian Trucker.

In 2004, Ersalle worked as a lecturer at Sunway University for two years but thought that position made him feel stagnant. “Everything was just theory for me. I always considered myself a businessman and as a businessman, I wanted to go out and do things, so I looked for a conglomerate and got the opportunity at UMW Toyota Motor Sdn Bhd.” There, he took up many challenges and described working with the Japanese as a tough experience as their culture is very field-oriented. Ersalle was in the after-sales team. “The Toyota way of running business is the kind of real-life situation that you need to be trained as a businessman,” he said.

After that Ersalle ran his own equipment business before coming across the opportunity to join Steelbro in 2012 where he started again from the ground level. He had helped to transform the company and initiated a sustenance programme which included financial support, after-sales services, production and spare parts. Steelbro also managed to control its credit collection through a new system and stock programme. “Steelbro used to be focused more on dealership, no after sales, but we have to be current and applicable to the Malaysian market,” he said.

Before becoming the Regional Manager, Ersalle managed sales operations where he brought in a new sales team. The business was then 40 percent sales and 60 percent after sales and parts. His team was careful about their expenses, ensuring that they did not spend on unnecessary things. “If cost was high, we would burden our customers. We always think about our customers but at the same time try to benefit our shareholders as well,” he added.

Although the brand has been in Malaysia for over 20 years, sideloaders were not very popular in the general market but Ersalle and his team have been convincing transport operators on the importance of sideloaders not only for their businesses but for the nation’s economy, too. Today production has increased and Ersalle is looking for a bigger space and planning to grow his team.

He acknowledged that the industry is not a glamorous one that attracts the younger generation but for the aspiring businessmen and businesswomen who love the challenge, Ersalle said that the transportation and equipment industries are the places to be. “This is hardcore business. People tend to look at the luxurious side of business, but it can be gruelling. In the car business, you deal with the general public, they are your customers but here (equipment business) you deal with other business people in the market, they are hardcore business giants. Working with them is a real adventurous journey. This is better than any certificate. Whether you win or lose, the experience is yours. People can take things away from you but not your experience.”

“If our youngsters want to be real business people, they should venture into this industry. It took me a while to understand the concept, but it has enhanced my soft skills as I managed our limitations in order to achieve our target. These challenges shape a person and increases critical thinking skills. At Steelbro we solve at least 10 problems a day without compromising our target. The service industry market is such that everything is urgent, and every decision is money. Also, of course, this industry can offer you big packages. If you are good at what you do, you can really make money here,” Ersalle said.

First published in Asian Trucker Trailer Special – Thought Leaders

read more

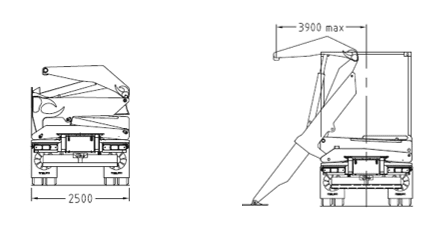

The Steelbro engineering team have invested a lot of design time to achieve the best possible geometry for the SB450 crane. The demanding requirements brought on by the various tasks a sidelifter must be capable of completing means that the position of the arm pivot points and the actual arm length had to be optimised to ensure all of the tasks could be completed.

This is a challenging job as any small adjustment has a major effect on the final performance and often one small adjustment to improve one function has a large negative effect on another function.

The Steelbro team had to develop a geometry with a large outreach. This is a vital element as often it is difficult to position the trailer close to the container that is going to be lifted. Having the large outreach allows the operator to be able to pick up the container even though the trailer is some distance away.

This large outreach is also an important feature when performing a trailer to trailer transfer. A trailer to trailer transfer is when the sidelifter is used to load/unload a container onto or off from another trailer. During this process the companion trailer is parked as close as possible to the sidelifter and the container is then transferred. Having the large outreach allows extra distance between the companioning trailer and the sidelifter, making alignment much easier and avoiding collision damage.

Having the large horizontal outreach is great but the sidelifter also has to perform a double stack operation, A double stack is when the sidelifter is used to load/unload a container from on top of another container. During this function the container being moved has to be lifted very high to allow it to get above the lower container. The Steelbro optimised geometry achieves this feat very well and the container is capable of being double stack onto to the larger 9.6’ container.

A further feature of the Steelbro SB450 is its low profile stowed position. The cranes stowed in a low profile helps avoid damage from foreign obstacles when in transport and also helps avoid damage and contact with the container when being loaded by a straddle carrier.

Through relentless optimisation, the Steelbro team have developed the SB450 to achieve a large outreach of 3.9 metres whilst still being capable of performing a double stacking function on a 9.6ft container and keeping a low profile making it the ideal product.

First published in Trailer Tech – Asian Trucker Malaysia Issue 41

read more